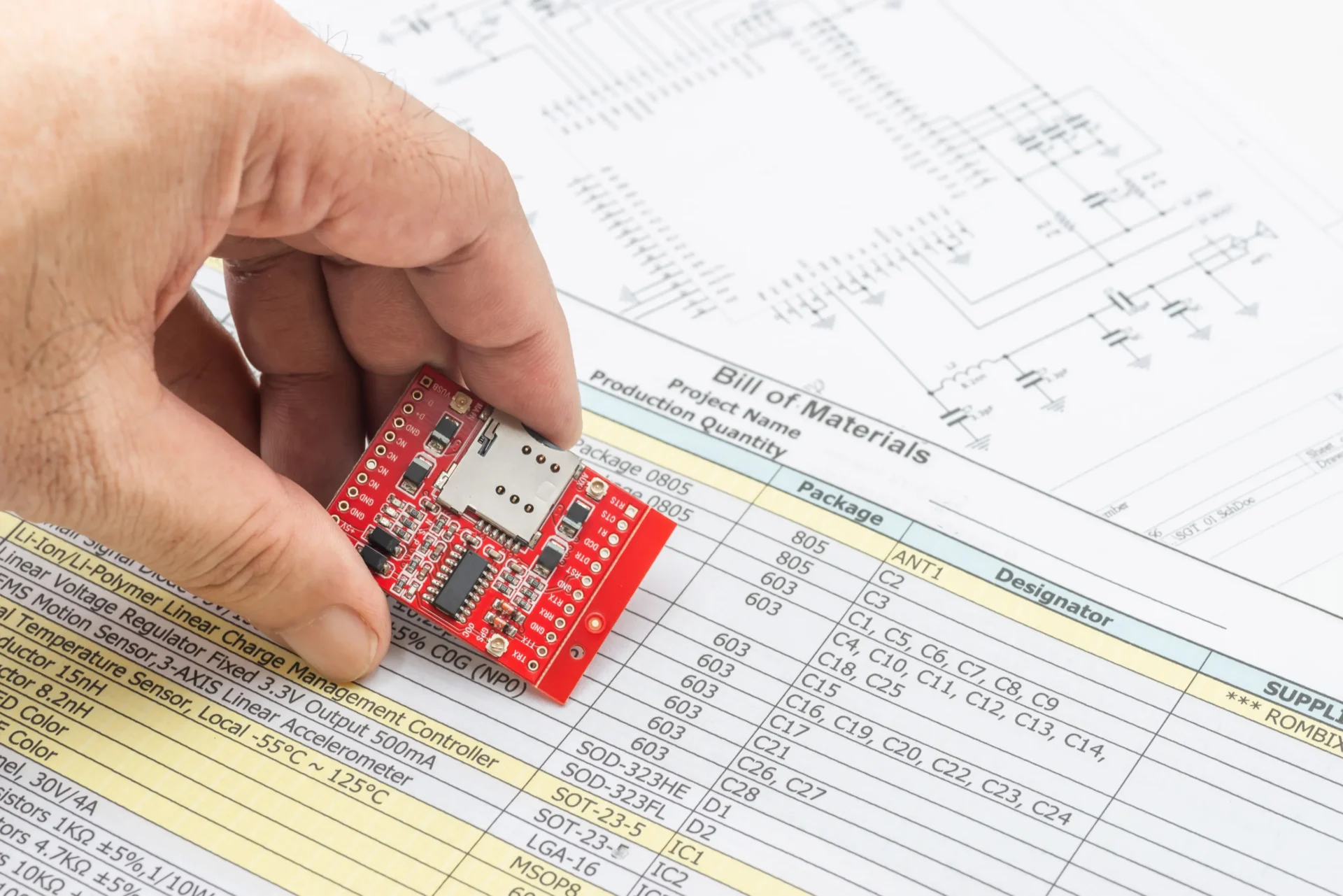

Let’s say you have a circuit board in hand, maybe it’s from a legacy product, a discontinued device, or a design you want to replicate or improve. But there’s a problem: you don’t have the original schematic or design files. Can you still recreate it?

That’s the question we hear all the time:

“Can I reverse engineer a circuit board into a schematic so I can reproduce it?”

The short answer is maybe — depending on how complex the board is and what your goals are.

Read on while our engineers walk you through what’s involved in reverse engineering a PCB, what the limitations are, and how we can help.

What Is Reverse Engineering a Circuit Board?

Reverse engineering a PCB (Printed Circuit Board) means taking a fully assembled board and figuring out what each component is and how they’re all connected — ideally recreating the original schematic diagram and layout files so you can reproduce or modify the design.

This is often done when:

- You’re modernizing old electronics

- The original design files were lost

- You want to manufacture more units of an existing product

- You want to update or repair something that’s no longer supported

What Makes Reverse Engineering Possible — or Not?

If you’re holding a circuit board and wondering if it can be reverse engineered, here are a few things to consider:

✅ It’s more likely to be doable if:

- The board is relatively simple

- It only has 1 or 2 layers

- The component labels are visible (so we know what each part is)

- The board doesn’t rely on custom programming or code

❌ It’s less likely to be doable if:

- The board is multi-layered (3+ internal layers)

- It contains a microcontroller or FPGA with protected firmware (software)

- It’s a specialized or high-frequency board where trace layout matters just as much as the schematic

- The component values and part numbers are scrubbed off or obscured

Even if the physical connections are mapped perfectly, some chips require internal code to work properly, and that code often can’t be extracted.

What About Just Tracing the Board?

On simple boards, reverse engineering can sometimes be done by:

- Visually inspecting the board to trace the copper tracks

- Using a multimeter to “buzz out” connections

- Making educated guesses based on experience

But with complex boards — especially ones with internal layers — it’s rarely that straightforward. In some cases, advanced tools like X-rays or even electron microscopes are required… and that’s typically not cost-effective for small-scale projects.

So, What’s the Best Path Forward?

In many cases, it’s actually faster and more cost-effective to analyze what the board does and create a new design from scratch. That way, you get:

- A clean, up-to-date schematic

- A modern PCB layout with the latest components

- Full control over the design, updates, and manufacturing process

That’s where our expertise in printed circuit board assembly and design come in.

What We Offer – Printed Circuit Board Assembly

We specialize in helping individuals and businesses recover, reproduce, or improve electronic products — even when no original files exist.

Depending on your board and your goals, we can:

- Identify components and create a new schematic from an existing board

- Recreate the board layout for small-to-mid scale reproduction

- Design a new board based on what the old one does (often more reliable and future-proof)

- Consult on microcontroller or firmware limitations so you don’t waste time chasing dead ends

Every project is different, and we’ll always give you an honest assessment of what’s possible — and what’s not.

Reach Out To Our Engineers Today

Reverse engineering isn’t magic — it’s technical, time-consuming work that depends heavily on what you’re starting with. But if you have a board and no documentation, don’t toss it just yet. Let’s take a look.

It may be possible to breathe new life into your old hardware. Our engineering team is located in Mesa, AZ. You’ll work directly with the engineers who will be assembling and designing your PCB. We don’t outsource or send your board overseas. Everything is done in house, so you don’t have to worry about your files disappearing and you’ll avoid paying high tariffs prices on PCB components. Contact us today to get started.

Blog Contributions by:

Peter Hall, President & Founder at Southrock Engineering