New to electronic manufacturing? No problem! We’ve defined a few basic electronic manufacturing and quality control terms that you might not be familiar with here. Have more questions?

Check out our FAQs.

We also have pages for:

A special type of file used to design PCBs. It tells the manufacturer where to place traces, holes, and text.

BOM stands for Bill of Materials. Every project at Southrock starts with a complete and accurate Bill of Material, that drives costing, purchasing, inventory, and even invoicing.

The technical staff that takes your order, also controls receiving, part delays, exceptions, and time management. BOM is much more than just a parts list.

DFM stands for Design for Manufacturing. This approach is important because it focuses on the original intent of the product’s creation. When you work with Southrock, you deal directly with the designers and engineers who will be working on your project from conception to completion. There is no middleman.

Your concepts and designs begin with an emphasis on manufacturing, efficiency, and cost. It’s all done right here, under one roof.

Automation in manufacturing involves using technology and machinery to perform production tasks with little to no human intervention.

However, there are many programs available that can “design a PCBA” using automation. We see this all the time. In most cases it won’t the most efficient design. The components might be too small or too tightly spaced, which drives the production cost up. There may be more PCB layers involved than necessary, driving up the bare PCB cost.

Computers do not take into account testing, future troubleshooting, or field repair access. An automated computer design never considers repair as a factor during initial design, in fact DFM is ignored for the most part. Sure, we could build these complex designs, there are plenty of non-engineering firms that “just build stuff”…but that is not how a proper engineering firm should approach a new project.

We make PCBAs at Southrock that have been in production for 40+ years, they fit the same envelope, they do the same functions, but the components are totally different. Projects can and should evolve when everything is done under one roof.

Custom made test equipment that ensures go/no go functionality. We write software test routines for PCBAs, as well. Likewise, we employ a variety of methods to ensure products meet quality standards and functional requirements before they are released to customers.

Acceptability of Electronic Assemblies, dos and donts, yes and nos, often explained with text and photos in an IPC standards manual.

The sudden flow of electricity (like a static shock) that can damage sensitive components.

Unwanted electrical noise that can disrupt the performance of circuits and wireless signals.

Our Services

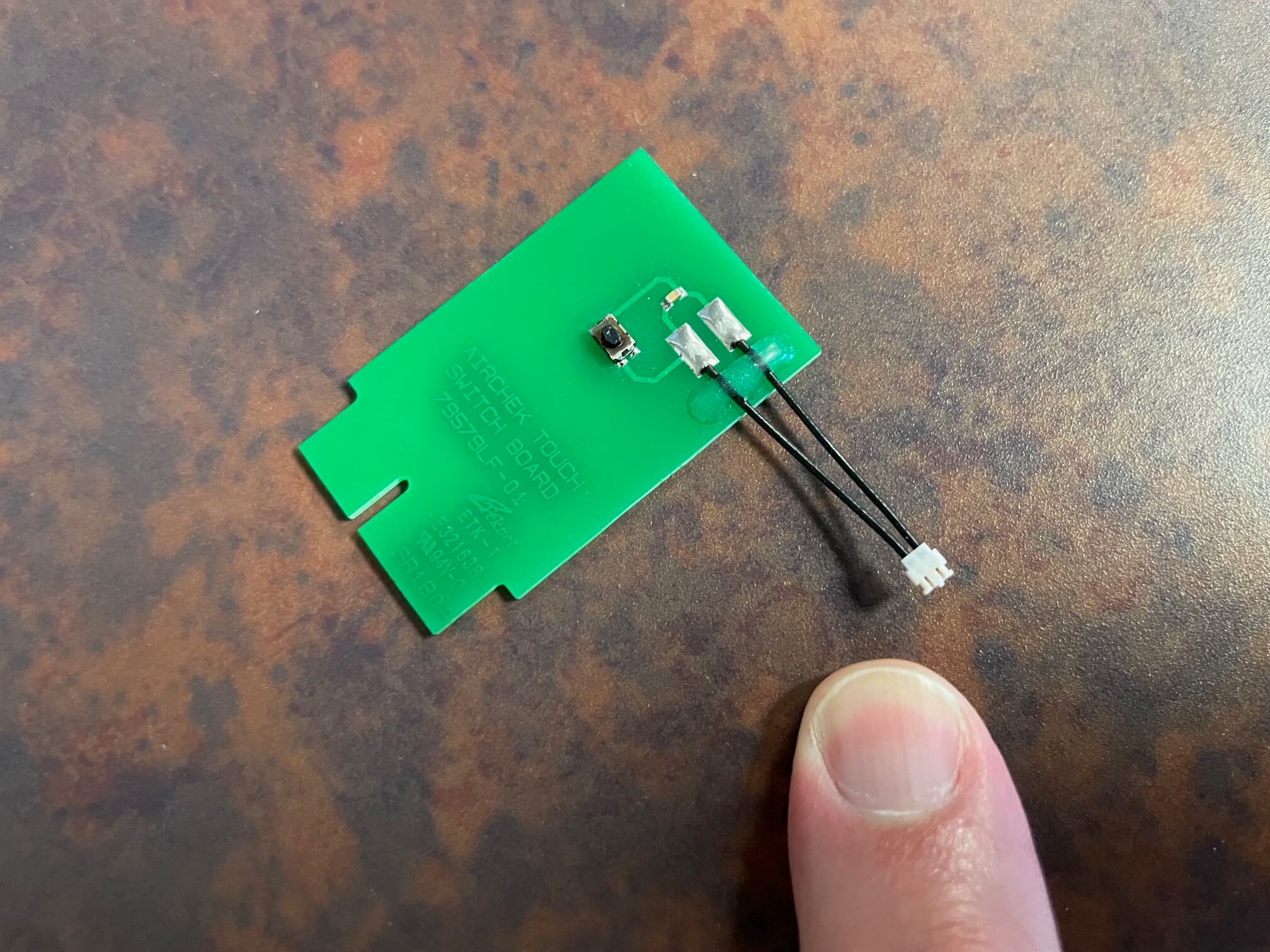

Printed Circuit Board Assembly (PCBA)

We design, assemble, inspect, program and test your printed circuit boards.

Custom Cable Manufacturing

We build custom cable & wire assemblies that meet your specifications.

Reverse Engineering

for PCBA

Outdated PCBA Designs? Offshore PCBA vendors? We can help.

Need a Quote?

Whether it’s Custom Printed Circuit Boards or Custom Cable & Assembly needs,

Our engineers are ready to assist you.