Electronics manufacturing moves fast, automation tools are evolving daily, promising everything from quicker turnaround times to reduced costs. From AI-driven PCB layout software to automatic quoting platforms and PCBA visualizers, it’s easy to assume that these digital tools have replaced the need for hands-on engineering collaboration.

Here at Southrock Engineering, we’ve been in the game long enough to know that these tools aren’t the enemy, as long as they’re used to work smarter, not harder. We believe the best results come from balancing automation with our engineering team’s decades of hands-on expertise—especially when it comes to Design for Manufacturing (DFM) and long-term product success. Let’s dive into what makes our team stand out from the rest when it comes to automation and engineering insight in PCBA and cable assembly.

Why Engineering Insight Still Matters

While PCBA design programs can speed up certain steps, they don’t always account for practical realities like part availability, thermal management, or repairability. Automated platforms may look impressive, but they often overlook key factors that affect cost, manufacturability, and future-proofing…basically all of the factors that drive DFM.

That’s where Southrock Engineering stands apart.

Rather than rely solely on visualizers or auto-checkers, our clients speak directly with experienced engineers throughout the design and manufacturing process. That early, direct communication often uncovers small details that automated platforms simply can’t flag—details that can prevent production delays, reduce rework, and ultimately save time and money.

When Digital Tools Fall Short in PCBA

It’s true that automation has its place:

- Automated quoting tools can provide fast cost estimates.

- PCBA visualizers offer a high-level view of the board.

- Software can run basic rule checks on a layout.

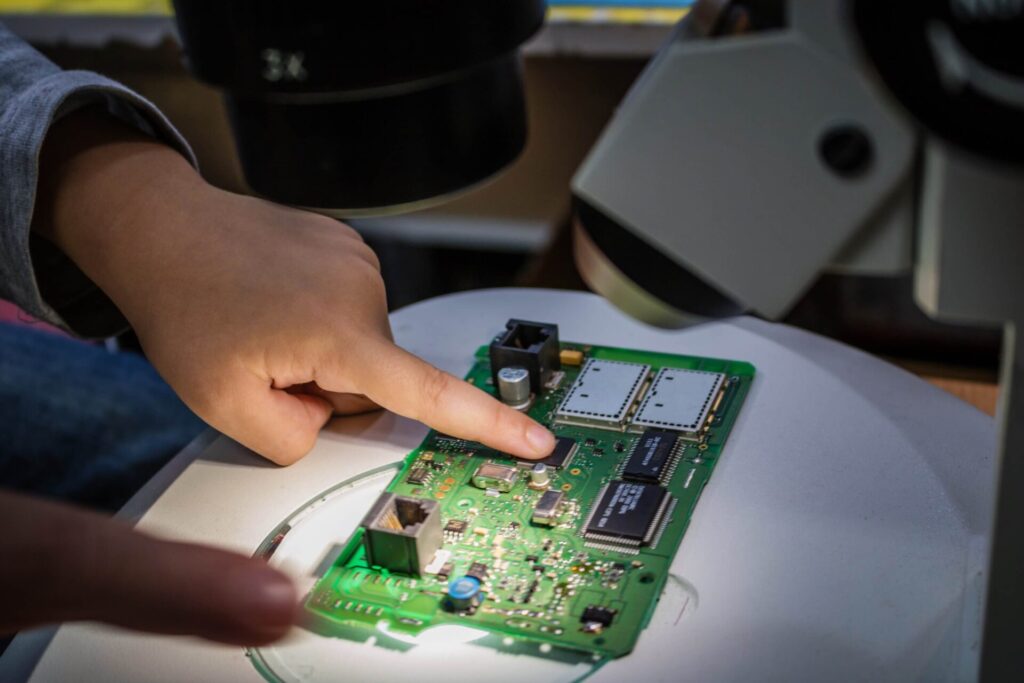

But these tools don’t tell you if a board is repairable, whether a part’s lifecycle matches your product roadmap, or how a connector’s orientation might affect field use. Additionally, a computer cannot reverse engineer a printed circuit board assembly, while an experienced engineer can.

A digital twin can’t replace an experienced engineer asking: “Can this be built better, faster, and more reliably?”

The Southrock Advantage: Design-for-Manufacturing is Top Priority

At Southrock, design-for-manufacturing (DFM) is top of mind from the very beginning. By integrating DFM principles early with direct engineer-to-engineer collaboration, we ensure that your designs are not only functional but also practical to assemble and scale.

When you partner with us, you get:

- Faster problem-solving: Our engineers quickly identify and solve potential issues before they reach production.

- Smarter designs: With DFM input from the start, we eliminate many of the common pitfalls that lead to production delays.

- Lower total costs: Fewer design changes, reduced scrap, and smoother production transitions translate to real savings.

We’re not a faceless offshore manufacturer, and we don’t make you communicate through layers of account managers. At Southrock, we keep the process human, responsive, and focused on your success.

Combining Strengths: Automated Tools + Human Talent

We’re not anti-technology by any means. We use modern tools to enhance visibility and improve timelines. But we also know that the best PCBA outcomes come when digital convenience meets hands-on expertise. For example:

- We’ll work with your CAD files, but we’ll also recommend layout tweaks based on real-world production feedback.

- We’ll provide clear documentation, but we’ll also walk you through complex cable harness design decisions to optimize routing and fit.

- We’ll get your prototypes built quickly—but we’ll also make sure they’re ready for scaled production.

We use automation and AI-integrated tools as just that…tools. You can hammer in a nail with a pair of pliers but it wouldn’t be the best idea. When you use tools the right way and for the right purpose, projects run more smoothly for everyone.

Ready to Build It Better?

Automation gets a lot of attention. Southrock Engineering wants to remind you that people still matter—especially when those people are seasoned engineers focused on building your PCBA and custom cable products right the first time.

Have an idea? Whether it’s custom printed circuit boards or custom cable and assembly needs, our engineers are ready to help. Reach out for a quote today.

Blog Contributions by:

Eric Crookston, Operations Manager at Southrock Engineering