Flexibility & Efficiency To Manage Everything From Sourcing & Assembly To Turnkey Management

Wire and cable assemblies are produced to IPC610 manufacturing and assembly standards. We are certified by UL and can supply UL labeling and documentation as required.

Watch how we BUILD your custom Cable Assemblies!

We build custom cable & wire assemblies that meet your specifications.

Southrock Engineering Inc. makes it simple to get the precise cables needed for your application. With an expansive selection of materials, we offer prototyping, development & design that will meet your specifications. Already have a design? No problem we can work with what you provide or help to optimize the design and manufacturing process to gain cost efficiency, quality and design objectives.

custom WIRE HARNESS ASSEMBLY

Southrock Engineering wants to help you create a successful product. Whether you have a finished schematic, a hand drawn sketch or require component substitution due to supply issues, our qualified engineers can provide the expertise you need.

cable drawing SCHEMATICS & PRE-BUILT

We have the ability to produce cable drawing schematics from scratch or reverse engineer an existing item. We’ll help with advising on wire gauges, crimp and soldered connectors & harness assembly. Producing Bills of Materials (BOMs) & advising on any cost saving options.

SINGLE TO MULTI

Regardless of complexity, or the requirement to combine various wire types and connectors into one harness our qualified engineers will work with you to achieve the required solution.

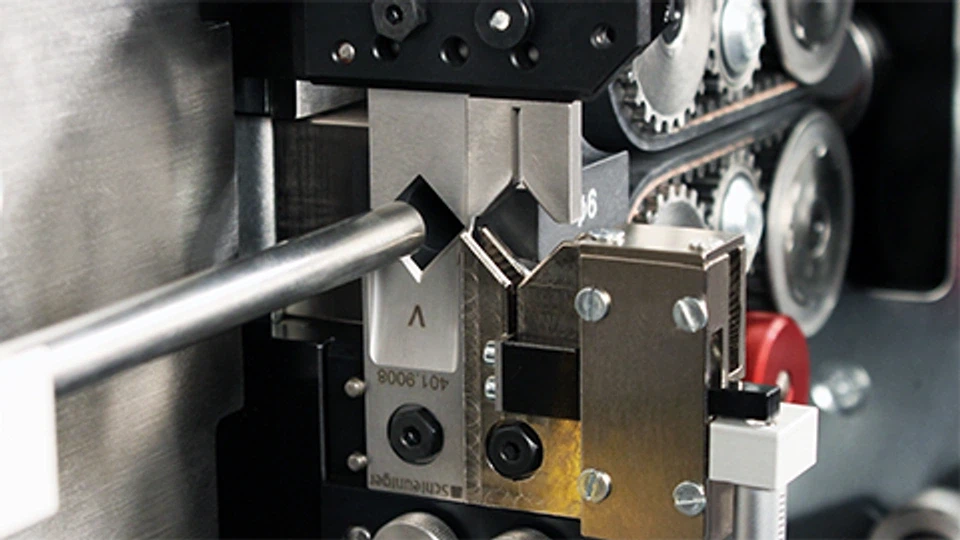

Cable Cutting, Stripping, and Terminating

Custom Cable Design, Assembly and Processing

Our custom cable design, assembly and processing services cater to a wide range of industries. We work closely with you to understand your specific needs, allowing us to create tailored solutions that fit your exact specifications. Our cables are designed for optimal performance, whether you need them for high-speed data transmission, power distribution, or specialized applications.

Processing Capabilities

Crimp Terminations

We offer precise crimp termination services that guarantee secure and reliable connections for your custom cables. Our automated crimping machines ensure consistency in every termination, reducing the risk of failure and enhancing the overall durability of the cable assemblies. Our team inspects each crimp to ensure it meets our high-quality standards, providing you with peace of mind.

Crimp Terminals

We stock a wide variety of crimp terminals suitable for various applications. Our crimp terminals are designed for compatibility with different wire sizes and types, ensuring a reliable and secure connection every time. Whether you need standard terminals or specialized options, we can provide the right solution to meet your requirements.

Bespoke Cable & Wire Prototyping

Custom Prototype Cables

Custom Box Builds

Frequently Asked Questions

A bundle of wires or cables organized together with protective sheathing, connectors, and terminals. It helps keep wiring neat, protected, and easy to install in complex electrical systems.

A set of wires or cables enclosed in a single protective sleeve, often with connectors on both ends. It is designed to efficiently transmit power or signals in various applications.

Wire processing means preparing raw wire for use. It can involve cutting it to the right length, removing the insulation (stripping), or adding connectors. It’s like getting a shoelace ready by cutting it and adding plastic tips (aglets) at the ends.

After a wire is processed (partially stripped of insulation) it can have a terminal placed on one or both ends.

A terminal is a metal connector that goes on the end of a wire, making it easy to attach the wire to something else. It can be a pin, socket, spade, or other shape.

Custom wire assemblies are used in industries like automotive, medical, industrial automation, and more.

A wire is a single conductor, usually made of copper or aluminum, while a cable consists of multiple wires bundled together, often with insulation and shielding.

Crimping is the process of attaching a terminal or connector to a wire by compressing it with a crimping tool, creating a secure and conductive connection without the need for soldering.

What’s the difference between a cable harness and a cable assembly?

The main difference between a cable harness and a cable assembly is how they’re organized and protected. However, when it comes to custom manufacturing, the terms can be used interchangeably due to the robust engineering of each. A single

wire is just that, a cable however consists of several wires together in one protected unit.

Cable Harness – A typical cable harness is a group of wires or cables bundled together with a simple materials like tape, zip ties, or sleeves. It keeps cables organized, but doesn’t usually provide significant

environmental protection. These types of cable harnesses are typical for those that you would find enclosed inside a protected structure, or inside an appliance, or behind the firewall of a vehicle.

The cable harnesses we build at Southrock however, are usually designed for industrial use. Some may be buried in the ground, or installed where they must withstand elements like dust, water, UV, oil or gas. Some of Southrock Engineering’s custom cable harnesses are very complex and specific. We also deal with assemblies down to 30 gauge, that transfer low power, or data.

Cable Assembly – A typical cable assembly can be as simple as the coax that runs from your wall, to the back of your modem, usually consisting of multiple wires inside of an insulation material. Multiple cables may also be bundled together inside of additional sheathing, to form an assembly.

Key Differences Between Cable Harness & Cable Assembly

Features

Cable Harnesses

Cable Assembly

Both

Need a Quote?

Whether it’s Custom Printed Circuit Boards or Custom Cable & Assembly needs,

Our engineers are ready to assist you.