What do you picture when you think of custom cables? A lot of people picture something like an extra-long or super short cord, a different connector, or a bundle of wires wrapped together “professionally”. But in reality, custom cable manufacturing is often far more complex, and we’re not just saying that because it’s our job. It’s the process of engineering a reliable connection between devices that were never originally designed to work together.

This case study breaks down a recent project led by Eric Crookston, Southrock’s Operations Manager, to show what “custom cable manufacturing” really means. It’ll also help clarify who our ideal clients are, what problems we solve, and how our engineering approach differs from “commodity cable vendors.” For teams who have never worked with a custom cable manufacturer before, this story will make the process easy to understand.

When Off-the-Shelf Cables Don’t Work

A customer came to Southrock after several failed attempts with another vendor. They needed a way to connect four existing sensors to an existing computer data monitor. Nothing about the system was new. The challenge was making everything work together without redesigning the equipment.

The previous vendor’s prototypes failed repeatedly. The signals weren’t reliable. There was interference between sensors. The cable didn’t meet the durability requirements. And the overall design didn’t account for the limitations of the existing hardware. Basically, this customer learned the hard way that they needed to hire an engineering partner. That’s when they found us.

Step 1: Understanding the Problem (and the Constraints)

Before Eric touched any tools, he met with the customer via Zoom to see exactly why the earlier attempts didn’t work.

He focused on two categories:

What Cannot Change

- The customer’s existing sensors

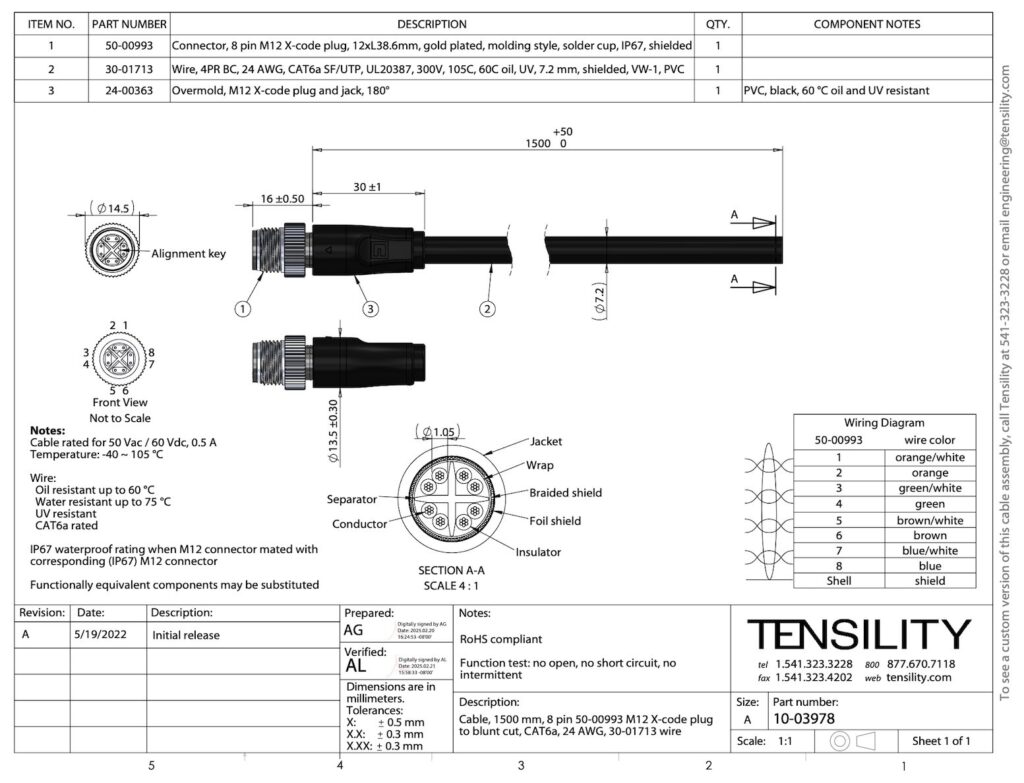

- The existing M12 X-Code connectors

- The computer’s 44-pin data input

- The physical environment where the system operates

This is where engineering experience matters. This isn’t a time for guessing. We reverse-engineer real systems and design cables that fit the electrical, mechanical, and environmental needs of that system.

What Can Change

- Design choices

- Cable construction

- Shielding Wire gauge

- Pin assignments

- Mechanical durability

Step 2: Selecting the Right Connectors and Wire Gauge

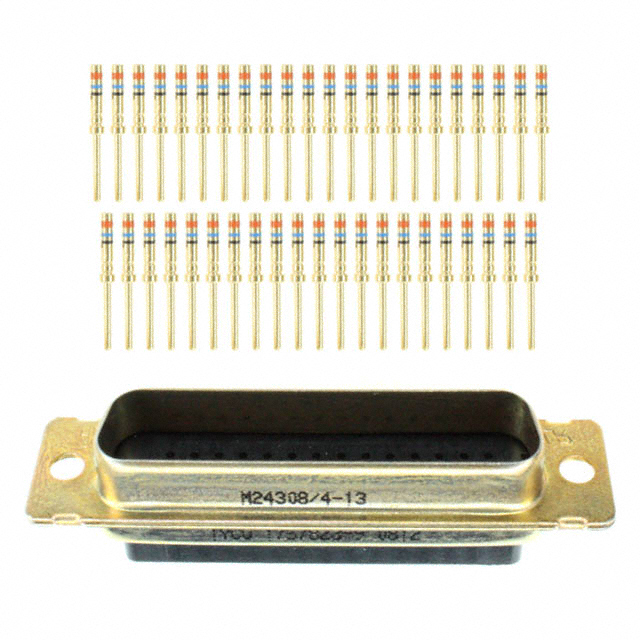

The computer’s data monitor required a high-density 44-pin male connector. Eric chose a military-spec connector with matching gold crimp pins. Why gold-crimp contacts? Because they ensure strong mechanical retention, low electrical resistance, and long-term reliability…especially important in multi-sensor applications.

The connector also established the correct wire gauge, which ensured the rest of the cable components were compatible. This is where other vendors fail: they try to make the cable fit the connector instead of engineering the full system.

Step 3: Transmitting Data & Power Through Four Sensors, Eight Wires Each – 32 Total Connections

Here’s where the real engineering challenge appeared. Ready?

Each of the four sensors requires:

- Power

- Data transmission

- Reliable signal isolation

That’s 8 wires per sensor — 32 wires total — all traveling through one custom cable assembly.

The biggest causes of failure in the previous vendor’s prototypes were:

1. Crosstalk – Signals from similar sensors were interfering with each other.

2. Power interference – Running power alongside data, without proper shielding, caused noise and data disruption.

3. Poor isolation – The previous design didn’t separate the internal wire pairs correctly.

Southrock solved all three issues in one decision: Knowing the sensors had existing eight-pin, M12 X-Code, round connectors, we started looking at CAT6a cable options. We chose the CAT6a cabling with double shielding, pair isolation, and a tight internal twist structure.

CAT6a is designed for:

- High-speed data (up to 10 Gbps)

- Low interference

- Maximum signal isolation

- Consistent electrical performance across long distances

Even though the application wasn’t Ethernet, CAT6a’s engineered construction solved the sensor-level electrical problems immediately. Eric also purposely kept the pin-to-wire connection lengths as short as possible to preserve shielding, a detail the previous vendor overlooked. This is the kind of nuance that comes from decades of engineering experience.

Step 4: Designing for Strength and Durability

The customer needed a connector assembly that could survive real-world use…plugging, unplugging, and possible field wear.

Eric selected a shielded, machined aluminum, two-piece back shell. Other types of back shells can deform, loosen, or allow EMI to penetrate the cable assembly. This design eliminated those risks and provides:

- A solid, professional interface for daily handling

- Strong mechanical protection

- Shielding against electrical interference

- Cable strain relief

- A solid, professional interface for daily handling

Step 5: Precision Assembly and Documentation

After all of those steps were taken, we document it all. Engineering requires clear documentation, so every assembly is consistent and traceable. Our technicians created a detailed wire-to-pin legend for all 32 connections, then:

- Labeled each of the four cables

- Tested each connection end-to-end

- Verified correct electrical continuity

- Confirmed isolation and shielding performance

This level of documentation is especially important for clients who plan to scale up production or return for future builds.

Step 6: Prototype → Approval → Production

Once the prototype passed every test, we moved immediately into production. The customer’s feedback was straightforward – they were very happy with our initial analysis of the project, timely prototypes, and production capabilities.

The cable worked the first time. The interference issues were gone. The assembly was stronger and cleaner than anything they’d received from the previous vendor. This is the true difference between a “cable vendor” and an engineering-driven manufacturer.

What Southrock Engineering Does (and Doesn’t) Do

A lot of people assume all electronics manufacturers do the same thing. This case study highlights where Southrock fits in the industry:

✔ What We Do

- Custom cable manufacturing

- Cable reverse engineering

- Connector selection + sourcing

- PCB reverse engineering

- PCBA design + assembly

- Vendor sourcing and supply chain management

- System-level problem solving

✘ What We Don’t Do

- Manufacture printed circuit boards (we design and assemble PCBA)

- Cut corners with generic materials

- Offer “plug-and-play” commodity cable solutions

Our ideal clients are those who need custom-engineered solutions, not off-the-shelf products.

Why This Matters for Novice Buyers

If you’ve never worked with a custom cable manufacturer before, you may not know what to expect. Here’s a simple explanation:

🚫 A cable vendor asks, “What cable do you want?”

✅ Southrock asks, “What problem are you trying to solve?”

That’s the difference.

Southrock Engineering:

- Diagnoses electrical and mechanical issues

- Reverse-engineers existing systems

- Selects the right connectors, wire, and shielding

- Designs for durability and safety

- Builds prototypes

- Produces consistent, repeatable assemblies

- Manages sourcing so your team doesn’t have to

This approach prevents failures, reduces downtime, and often costs less over the lifespan of the product.

Real Engineering. Real Solutions. Real Results.

This project is a perfect example of why custom cable manufacturing is more than just putting wires together. It’s engineering, and it’s where Southrock Engineering excels.

If you have sensors, devices, machinery, or systems that need to communicate reliably and off-the-shelf cables aren’t cutting it, Southrock can help diagnose the issue and engineer a solution that works.

Blog Contributions by:

Eric Crookston, Operations Manager at Southrock Engineering