Outdated PCBA Designs?

Offshore Vendors?

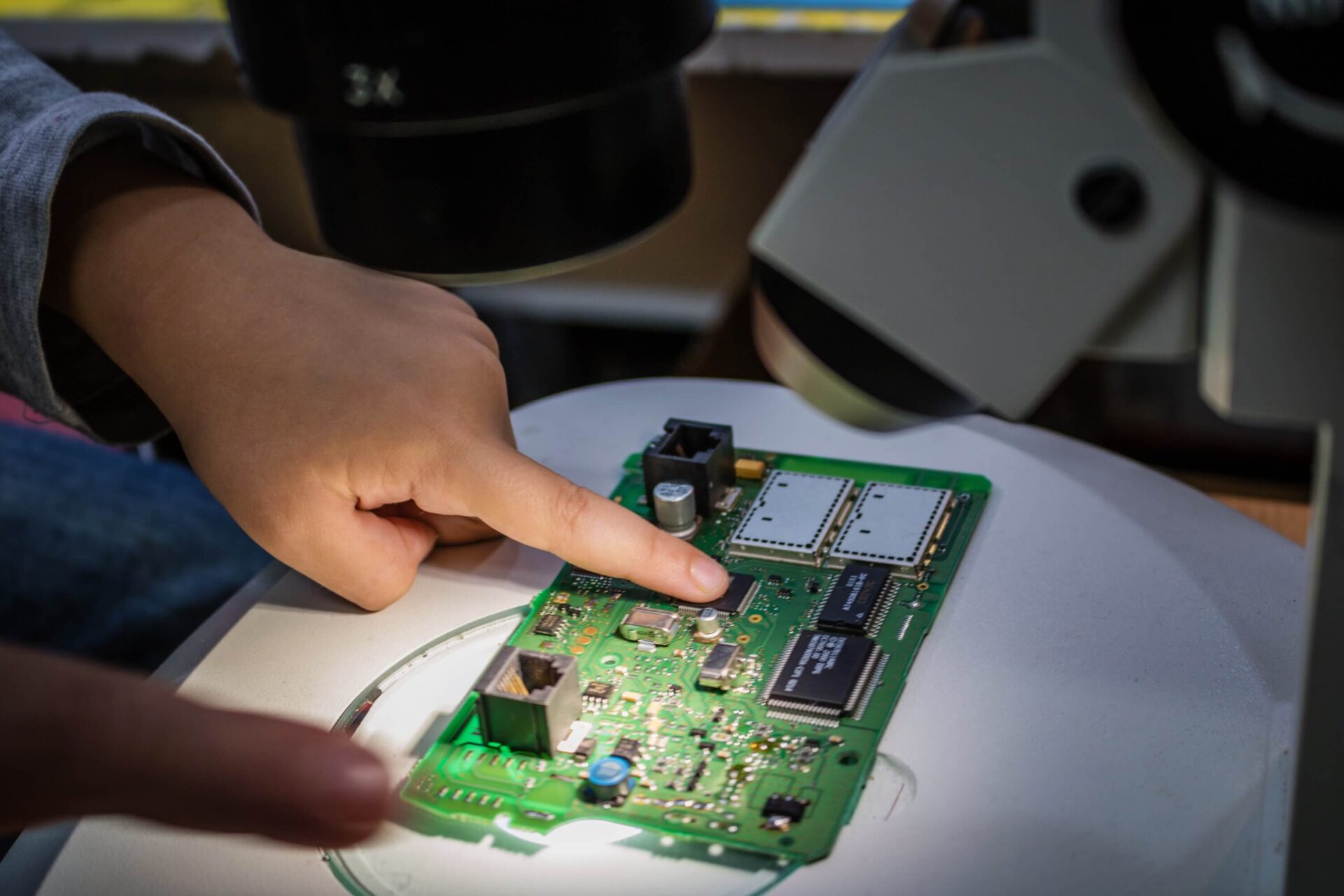

Our U.S. based engineering team is here to help solve your PCBA design problems. Whether you’ve got an older design with hard-to-source parts or an offshore vendor has your design and you’ve run into hurdles making changes, our PCBA reverse engineering services can keep your project on track.

Outdated PCBA Designs? You Have Obsolete or Expensive Components. We Can Help with Reverse Engineering for PCBA.

When you’re dealing with older PCB designs, hard-to-source or obsolete components can bring production to a halt.

Legacy designs often rely on components that are:

Looking for a practical, cost-effective solution for your legacy printed circuit boards designs?

You might start by searching online, but true answers come from experience. That’s where Southrock Engineering comes in. With decades of experience in PCBA design evolution and reverse engineering, we’ve helped countless clients modernize without starting from scratch. Our engineers help by:

Evaluating your existing PCB design in detail

Identifying and validating modern substitutes

Transitioning designs from through-hole to surface-mount components (or hybrids)

In-House, U.S. Based Engineers = PCBA Design Problems Solved

When you’re ready to move forward, Southrock is ready to help get you unstuck. All of our work is done in-house in the United States, ensuring quality, speed, and accountability from concept to completion. Learn more about how we can integrate custom manufacturing for your prototypes or box builds.

Intelligent component substitution

We evaluate your design and recommend equivalent or superior parts that are easier to source, without compromising performance.

Full or partial redesigns

Whether you need a small tweak or a complete update, we modernize your board while maintaining compatibility with your existing system.

Custom hybrid solutions to match form, fit, and function

We combine old and new technologies when needed, delivering creative solutions that preserve the look and operation of your original design.

I never thought of that!

That’s the phrase we hear most from new customers. The good news is, Southrock is a partner that solves the problem, not just sells a service.

Ready to talk?

Whether you’re facing obsolete components, long lead times, or evolving specs, Southrock Engineering has the experience and creativity to keep your project moving forward.

Struggling with Offshore PCBA Vendors? Here’s How Southrock’s U.S. Based Engineers Can Help

We’ve worked with countless clients who hit a wall when trying to update or improve their PCBA design, especially when their current vendor is overseas. If that’s your situation, you’re not alone. We see this all the time.

Your design is locked up with an offshore vendor, and now you’re facing:

Making a change shouldn’t feel like moving a mountain. We can help.

PCBA Design Changes Shouldn’t Be This Hard.

At Southrock Engineering, we don’t just build PCBAs. We build relationships and we understand full project workflows.

Reverse engineer existing assemblies

Prototype and test quickly

Handle revisions in real-time

Collaborate directly with your in-house team

And we do it all right here in the United States, so you can skip the shipping delays, time zone issues, and frustrating email chains. If you’re in Arizona, you can even come visit our shop in Mesa.

Total Transparency. Zero Hurdles. Full Control.

When it comes to PCBA design or redesign, access is everything. With Southrock, you’ll always:

No barriers. No black boxes. Just smart engineering and clear communication.

Ready to talk?

If your offshore vendor is slowing you down, let Southrock Engineering give you back speed, clarity, and control.

Industries and Applications

As an RoHS compliant shop in Mesa, AZ designing and assembling printed circuit boards and custom cable harnesses, we proudly serve health, safety , and utility markets – including but not limited to those in aerospace and defense, commercial, industrial, marine, telecom, automotive, energy, and lighting industries.

Why Choose Southrock Engineering?

Our USA headquarted team is located in Mesa, AZ. We produce both printed circuit board assemblies and cable assemblies to IPC standards. We’re certified by UL and RoHS compliant.

No Minimum Orders

Our US-based facility allows flexibility in order quantity. Need 10 or 1,000? No problem!

No Long Lead Times

Our engineers are in Mesa, AZ. We offer quick turnaround on PCB assembly & custom cables.

Freight Savings

Working local means quicker answers to all of your questions and freight savings, too!

Local Engineers

We are a team of engineers handling your ideas, orders, every project need, from concept to completion.

Come Visit Our Facility

We are your neighbors! Located in Mesa, AZ, we encourage and invite you to come visit.

New to electronics manufacturing? No Problem.

We’ve defined a few basic PCB soldering and assembly terms here

. Have more questions?

Check out our FAQs.

We also created glossaries for:

Basic PCB and PCBA Terms

Learn what printed circuit board assembly terms like trace, layer, silkscreen, and more mean.

Electrical Component-Related Terms

Learn what electronic component-related terms like capacitor (cap), resistor, diode, and more mean.

Manufacturing & Quality Control Terms

Learn what electronic manufacturing and QC terms like Gerber file, BOM, and more mean.

Need a Quote?

Whether it’s Custom Printed Circuit Board Assembly or Custom Cable needs,

our engineers are ready to assist you.