Frequently Asked Questions about PCBA & Custom Cable Manufacturing

Have Questions about One of the Industry Terms You See Here?

New to electronic manufacturing? No problem! We’ve defined a few basic terms that you might not be familiar with in our glossaries. Have more questions? Send us a message and we’re happy to add to the list!

In short, PCB is the empty board, while PCBA is the assembled and ready to function board.

PCB refers to the bare, unassembled circuit board, which consists of layers of fiberglass, copper traces, and other materials but does not yet have electronic components soldered onto it.

PCBA refers to the fully assembled circuit board, where all the necessary electronic components (resistors, capacitors, ICs, etc.) have been soldered onto the PCB, making it a functional electronic device.

Southrock Engineering specializes in PCBA and can help with any projects you have in mind, from concept to completion.

RoHS stands for Restriction of Hazardous Substances. It’s a rule that makes sure electronics don’t have dangerous materials like lead or mercury. This keeps electronics safer for people and the environment. Also known as Directive 2002/95/EC

NOPB means “No Lead” (Pb is the chemical symbol for lead). It tells you that the material or solder in the component doesn’t contain lead, which is better for health and the environment.

Solder stencils are special templates used to precisely control the placement of solder paste onto PCB component pads.

Reflow soldering is a way to attach electronic parts to a PCB using heat. First, solder paste is put on the pads, then components are placed on top. The whole board goes through a special oven that melts the paste, sticking the parts in place.

To manufacture and assemble a PCB, we need a few key files: Gerber or ODB++ files (which show the board layout), a Centroid file (tells us where to place each part), a Bill of Materials (BOM), and any special requirements you might have. Assembly drawings and any preliminary files are also helpful. Basically, tell us what kind of bare board you need, list out the components with quantities, and show us exactly where they go. There can be more detail depending on your project, but these are the essentials.

A good standard to follow is the CAD format known as DXF. It’s widely used and makes it easier to share schematics clearly.

IPC-A-610 is a quality standard for electronic assemblies. It lays out the do’s and don’ts of what’s considered acceptable, often with helpful photos and explanations. If you want to know what a good solder joint or clean assembly should look like, this is the go-to reference.

A PCB (printed circuit board) is made up of layers—like the core board, copper traces for conducting signals, ground planes, and the silkscreen which shows labels and part outlines. All of these come together to form the full structure of the board.

A PCB pattern is the layout of conductive and insulating paths on the board. Think of it as a detailed map that shows where electricity can and can’t flow.

Surface mount technology (SMT) refers to components that are placed directly onto the surface of a PCB, either by hand or by a machine. It’s a common method used for modern electronics because it’s efficient and saves space.

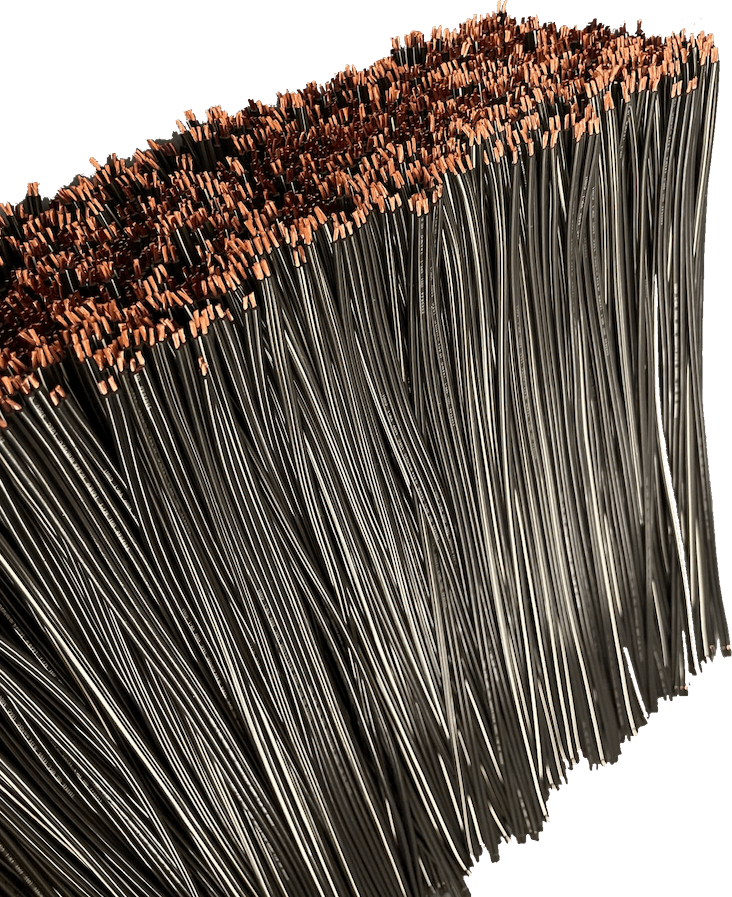

A bundle of wires or cables organized together with protective sheathing, connectors, and terminals. It helps keep wiring neat, protected, and easy to install in complex electrical systems.

A set of wires or cables enclosed in a single protective sleeve, often with connectors on both ends. It is designed to efficiently transmit power or signals in various applications.

A wire is a single conductor, usually made of copper or aluminum, while a cable consists of multiple wires bundled together, often with insulation and shielding.

The main difference between a cable harness and a cable assembly is how they’re organized and protected. However, when it comes to custom manufacturing, the terms can be used interchangeably due to the robust engineering of

each. A single wire is just that, a cable however consists of several wires together in one protected unit.

Check out our

Custom Cables page to learn more.

Our Services

Printed Circuit Board Assembly (PCBA)

We design, assemble, inspect, program and test your printed circuit boards.

Custom Cable Manufacturing

We build custom cable & wire assemblies that meet your specifications.

Need a Quote?

Whether it’s Custom Printed Circuit Boards or Custom Cable & Assembly needs,

Our engineers are ready to assist you.