To say that the electronics industry is moving quickly would be the understatement of the century. With everything from medical kiosks in the health and safety industry to interactive display lighting for LED and lighting solutions, and just about any other analog, digital, or microprocessor-based product you can imagine, the cost of printed circuit board assembly and custom cable manufacturing cannot be overlooked when considering your overall product’s budget and success.

Whatever your industry, Southrock Engineering can help. We have the experience, expertise, and track record to keep your electronics project on budget and schedule without sacrificing quality. Let’s talk about how our team of engineers, conveniently located in Mesa, AZ, can help save you time and money on PCBA through smart design, efficient sourcing, and our decade’s worth of experience.

Early Involvement in PCBA Design

We covered keeping PCB assembly costs down while delivering quality in our last blog, but it bears repeating, that one of the biggest ways any PCBA company can save you money is by getting involved early and often. Here at Southrock, we work closely with our clients from the very beginning of every project. This helps to prevent costly reworks and last-minute changes. It helps us to keep your projects on track and within budget.

Real-World Example: Fast-Tracking Air Sanitation Systems

Like most industries, electronics manufacturing didn’t escape the clutches of the pandemic supply chain issues. We had a customer who needed a control box for UV lamps and circulating fans for small spaces. And like most instances in the pandemic, they needed it fast. With just an idea to start, our team engineered a turnkey solution, handling everything from design to sourcing, manufacturing, testing, and certification in just a few months. The result? A cost-effective, high-quality product delivered on time, with no expensive design revisions, and most importantly – a happy customer.

Leveraging Bulk Purchasing Power to Cut Costs

Another cost-cutter we’re proud to have refined over the years is volume production and supply chain management. We’ve worked hard to build strong supplier relationships that allow us to secure favorable pricing through bulk purchasing agreements.

For example, by placing blanket orders, customers who commit to purchase orders (POs) over a year can benefit from lower costs. We can buy tens of thousands of bulk color LEDs, wires, terminals, and connectors, ensuring availability when needed and stabilizing prices against market fluctuations, all the while passing those savings on to the customer.

Navigating PCBA Supply Chain Challenges with Smart Solutions

When assembling printed circuit boards, component shortages can bring production to a halt. It’s a lot like baking a cake without all the ingredients. With a single PCBA, you can have everything from microcontrollers (MCUs), microprocessors (MPUs), integrated circuits (ICs), diodes, transistors, resistors, capacitors, inductors, connectors, relays, Ferrite beads, and the list goes on and on. Miss a capacitor here or a relay there and the whole design stops until you get the part you need or find a workaround. Thankfully, Southrock’s expertise in supply chain navigation and printed circuit board assembly keeps projects moving. Our direct connections with vendors—both domestically and overseas—allow us to source hard-to-find components even during global disruptions.

Real-World Example: Overcoming PCBA Supply Chain Shortages

During the pandemic, when many manufacturers faced production delays due to unavailable parts, we worked with specialized vendors who had direct contact with China to secure critical components. On top of that, our engineering team identified suitable component alternatives, preventing costly project halts. Unlike manufacturers that follow a Bill of Materials (BOM) without questioning or suggesting alternate solutions, our adaptive approach ensures jobs get done—even in challenging market conditions.

Touching on How Tariffs May Benefit Southrock Customers

With shifting tariffs affecting global manufacturing, Southrock provides an advantage by offering flexible, small minimum order quantities (MOQs). Unlike offshore suppliers that demand large orders, we can fulfill custom projects with as few as ten units. As a bonus, our strong vendor relationships have enabled some vendors to agree to share tariff costs, ensuring more competitive pricing for our customers.

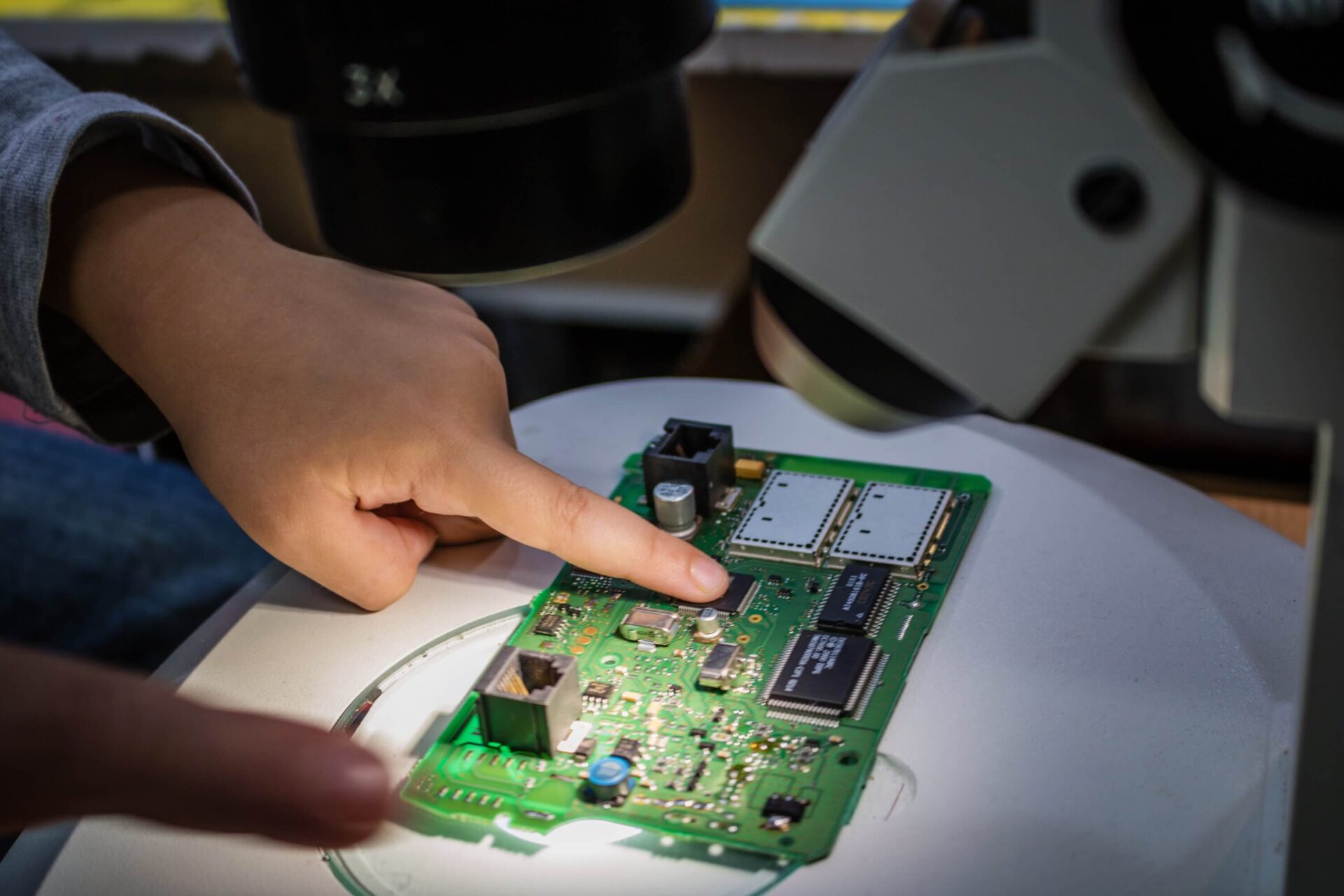

Quality Assurance: Getting It Right the First Time

We take pride in building things right the first time. While many manufacturers rely heavily on post-assembly testing, our meticulous approach minimizes the need for rework. When asked about our QA process, we joke that if someone wants to see our return log, we’ll have to blow the dust off it first. Every project that leaves our shop meets and exceeds IPC industry standards. When we say we care, we mean it and it shows in our work. We’ve developed custom test equipment to validate go/no-go functionality before products leave the facility. Our track record speaks for itself. Our eye for detail pays off with fewer failures, lower costs, and higher customer confidence.

Engineering for Longevity and Efficiency

Many of the PCBAs Southrock builds have been in production for over 40 years—evolving in components but maintaining consistent form and function. Unlike firms that simply “build stuff,” our team engineers products for long-term success, considering future troubleshooting and repairability from the outset.

Why Choose Southrock Engineering?

- Local Expertise: Located in Mesa, AZ, we provide hands-on collaboration and fast turnaround times.

- Cost-Effective Solutions: Bulk purchasing power, smart sourcing, and optimized designs help customers save money on printed circuit board assembly.

- Supply Chain Reliability: Strong vendor relationships ensure PCBA component availability, even during shortages.

- High-Quality Standards: Decades worth of experience in industries like health and safety, automation and control systems, LED and lighting solutions, and more ensure reliable, long-lasting products.

- Flexible Production: No large MOQs required—custom PCBA and cable manufacturing projects get the attention they deserve.

Partner with Southrock Engineering Today

If you’re looking for a manufacturing partner that helps you cut costs without cutting corners, Southrock Engineering has the expertise and capabilities to make it happen. Contact us today to discuss how we can bring your PCBA or custom cable project to life with efficiency, reliability, and quality you can trust.

Blog Contributions by:

Eric Crookston, Operations Manager at Southrock Engineering